While the legal hemp industry is relatively young, overproduction and a CBD market saturated with hundreds of brands have made for fierce competition. In addition to satisfying the legal requirements that come with running a hemp business, numerous entrepreneurs in the sector are looking to traceability solutions to differentiate their products and prevent counterfeiting, among other goals.

In this article, Hemp Benchmarks provides an overview of cannabis traceability as it relates to hemp, as well as some examples of how industry stakeholders and businesses from other sectors are utilizing new technologies and protocols to track their products from the field to the consumer.

Why Traceability?

Since the beginning of adult-use cannabis legalization in Colorado and Washington State in 2014, a variety of “seed-to-sale” software tracking systems have been established and adopted by state governments and cannabis businesses. Those systems act as a state’s primary inventory tracking program of record, ensuring cannabis products are cultivated, processed, tested, transported, and sold according to state law.

These track-and-trace technologies assist state officials in regulating their local cannabis markets by providing chain of custody information to facilitate product recalls and address potential issues, such as counterfeiting or diversion of product outside the licensed system. Additionally, consumers interested in ensuring product was produced legally and tested for safety benefit from traceability programs.

The 2018 Farm Bill that legalized hemp removed that variety of cannabis from the federal controlled substances list. As a result, hemp is generally not subjected to the stringent traceability requirements found in adult-use and medical cannabis markets where high THC products are produced, which typically include applying radio frequency identification (RFID) tags to each individual plant and batch of harvested product. However, the potential for hemp crops to exceed the legal limit of 0.3% THC – and therefore become an illegal controlled substance, technically speaking – means that some form of tracking and accountability for hemp is required by state and federal laws.

How is Hemp Tracked and Traced?

Due to hemp’s potential to generate THC in excess of legal limits, federal and state laws require crops to be sampled and tested for THC potency ahead of harvest, resulting in a lab issuing a certificate of analysis (COA). If the crop tests under the legal THC limit and therefore passes, the COA is then used by regulators, law enforcement, and other businesses in the supply chain to verify that the hemp was indeed produced legally under state and federal law.

Notably, COA requirements are not “traceability” in the sense that such practices are conducted with high-THC products in legal adult-use and medical cannabis markets. As noted above, in those systems each individual plant and product batch is generally tagged and theoretically able to be monitored at any point in the cultivation process or supply chain. With hemp, on the other hand, a legitimate COA for one crop could hypothetically be associated with another crop that it does not actually apply to. There have also been numerous accounts of COAs being forged or falsified.

Some states – including Colorado, Oregon, and Illinois – have created pathways for hemp products to be sold in the states’ licensed cannabis markets. In those instances, hemp products generally become subject to the same traceability requirements as other cannabis products. However, the vast majority of hemp products are sold outside these systems. For example, since the start of Oregon’s legal adult-use cannabis market in late 2016, industrial hemp products have accounted for only 0.8% of overall sales as of August 2021.

Why Would Hemp Businesses Want More Sophisticated Traceability?

Why would hemp businesses want to subject themselves to the extra overhead that comes with enhanced traceability if it is not required? With hemp-derived cannabinoids such as CBD, there are still many concerns about how cultivators, processors, and manufacturers can maintain a steady and stable supply chain for their products. Consumers, said Jacqueline Shan, “want high quality … they want to know what the potency is, and the traceability and the consistency. Consistency is very important, because you don’t want to have [it measured by] one batch.”

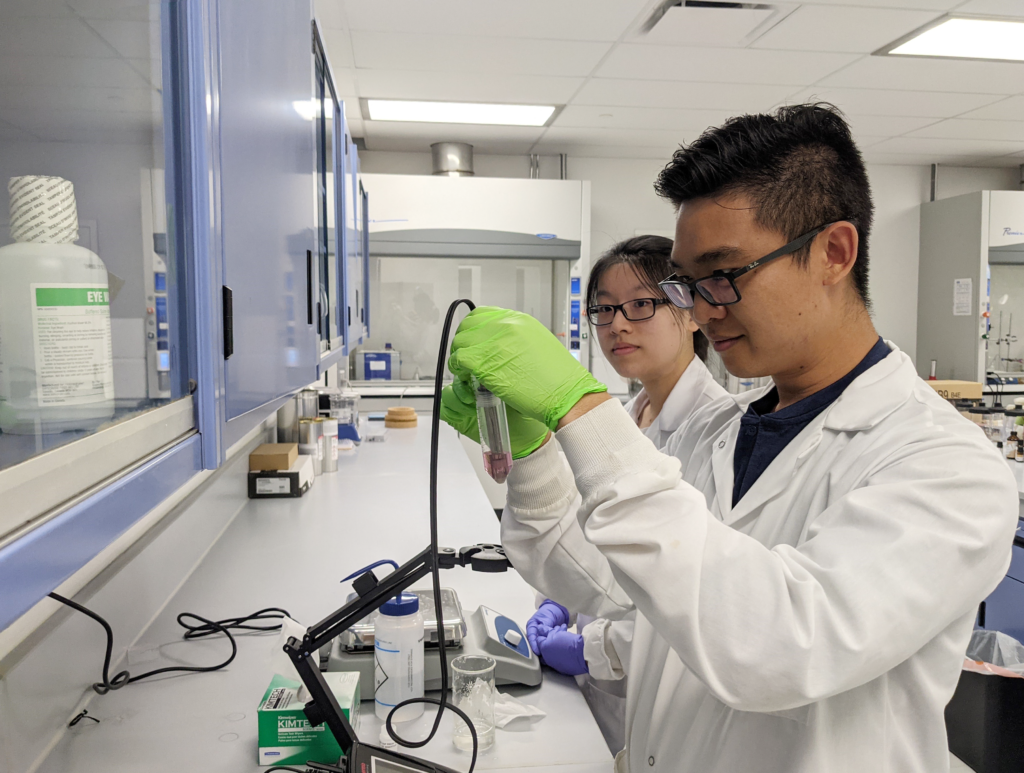

Shan is the founder, President, and CEO of Alberta, Canada-based PBG BioPharma, a vertically integrated biopharmaceutical company that focuses on research and development, testing, and the manufacturing of nutraceuticals and biopharmaceuticals, including “science-based” cannabis products. The company recently received a processing license from Health Canada to begin commercial-scale cannabis and hemp manufacturing operations.

Traceability, she added, is needed in the hemp sector “because there are a lot of myths. In Canada, it’s extremely important for the industry to self-regulate. We also need to create technology with an innovative approach, to ensure product’s traceability. That’s the only way you can gain confidence from the public.”

Shan explained further that, by employing traceability protocols, “the company also has less business risk. You don’t want recalls. [That’s] the beauty of that kind of healthy ecosystem in the market. The public understands health and awareness. It’s very important to educate the public and to give them confidence in the industry.”

What New Technologies are Being Used in Hemp Traceability?

PBG BioPharma employs a proprietary “triple fingerprinting” technology platform that uses chemical, biological, and genomic tracking to ensure that hemp product consistency, traceability, purity, and potency match or exceed local regulatory requirements. According to Shan, the procedures they use involve proprietary technologies that determine the hemp’s DNA, and then differentiate different hemp cultivars using those genetic markers.

Shan told Hemp Benchmarks that traceability needs to go beyond genetic markers, especially if there are concerns about contamination in the hemp products. “It’s also very important to ensure the chemicals that they have in the [hemp] profiles are consistent and traceable,” she said. With chemical fingerprinting, she added, a company can find out more about their products’ cannabinoid content, as well as the composition of other active ingredients, all the way back to the product’s raw materials.

Companies that specialize in traceability for industries such as textiles, pharmaceuticals, agriculture, and even the military are applying some of their cutting-edge technologies towards hemp traceability efforts. Applied DNA Sciences, a Long Island, New York-based firm, was approached several years ago by a cannabis company to see if their molecular tagging and authentication technology could be used with hemp products.

“So we engaged with [that company] and for the first year we did testing on all kinds of oils and isolates, using different extraction methods,” John Shearman, Applied DNA Sciences’ Vice President of Marketing, told Hemp Benchmarks. “By half of that first year we were able to say yeah, this is going to work.” Shearman said his company can apply DNA sequencing data in a liquid solution directly to hemp plants or extracts. This molecular tag, he added, is used in miniscule amounts, measured by parts per billion, and reportedly can be ingested with no problems.

“The minute that the molecular tag leaves our facility in Stony Brook, Long Island … that’s when the tracking and chain of custody starts,” he added. “The information goes into a cloud-based database that the customer can access.” All that data, he continued, can then be uploaded into any ERP (enterprise resource planning) software or seed-to-sale system. “So now you can see the trail of how the chain of custody can go all the way back to the origin point. We can prove that that tag was used in that facility, on that batch.”

The result, Shearman said, is a tracking system that cannot get lost or manipulated by outsiders. “There’s no better way than putting a physical identifier on the actual product,” Shearman added. “Once you harvest that plant and it goes into oils or it’s sold as a plant, at that point you start losing the traceability or chain of custody. By using our solution and complementing seed-to-sale systems, we feel that brings a totality of a full solution, all the way from seed to that end customer at the dispensary. That’s where transparency really comes out; is that you can tell that whole story now to the end customer, by using scientific forensic traceability.”

Can Traceability Be Used for Industrial Hemp Products?

This desire for enhanced traceability in the hemp industry extends beyond CBD and other hemp-derived cannabinoids. In late June, Texas-based Panda Biotech, a company in the emerging U.S. industrial hemp fiber and hurd industry, announced it had signed a Memorandum of Understanding with Oritain, a New Zealand scientific traceability company, to develop what they describe as “the world’s first fully traceable, hemp fiber.”

In a company press release, Panda Biotech said their partnership with Oritain allowed them to be sure “that all of the hemp fiber they produce is authentic U.S. hemp, grown by farmers in the state of Texas, passing on those assurances to their brand partners and the consumer.”

Will Traceability Become Commonplace in the Hemp Sector?

Demand for hemp product traceability, noted PBG BioPharma’s Jacqueline Shan, is rising. “I do hear that, even from our international buyers,” she said. ”The industry is evolving and it’s kind of understandable. A few years back it was pretty confusing, without clear regulations; it was hard to follow. With more countries legalizing hemp they demand traceability. [And with] more competition, it’s really pushing the industry to become better.”

John Shearman believes the hemp sector could end up leading the way in traceability technology development. “The cannabis industry is a clean canvas and they’re using all the state-of-the-art technologies,” he said, “so that’s why I think cannabis is going to do so well, because there isn’t a lot of legacy systems out there. And we can use best-of-breed technology systems, to allow us to trace everything from seed to shelf, and then provide transparency ultimately to the consumer.”